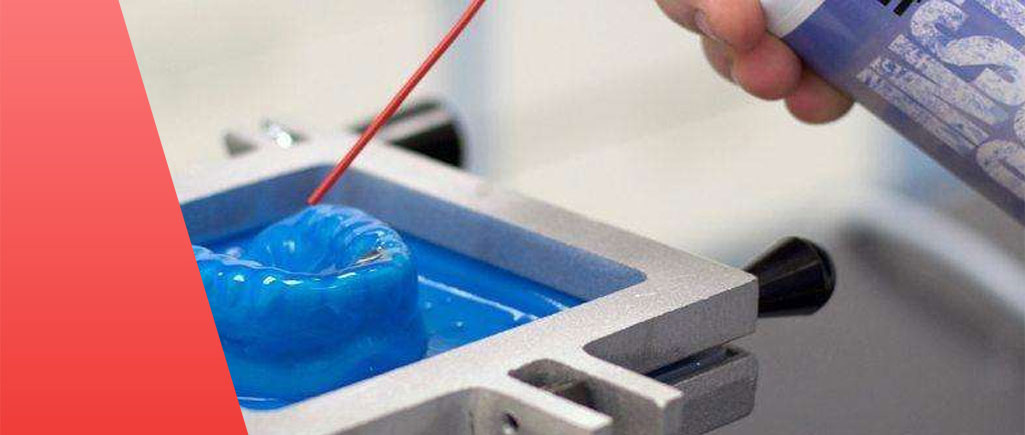

3 the hot plastic sheet is then forced against a mold by introducing both com pressed air on the top surface and vacuum in the tool cavity to evacuate the.

Instructions thermoform plastic sheets.

The sheet is pulled into the mold with a vacuum.

The plastic hardens and forms the desired part.

When you remove the plastic from the oven the surface of the sheet will cool off very quickly so you do not have much time to actually form the material usually only seconds.

Many plastic sheet materials can be shaped by thermoforming.

Thermoforming sheets kits.

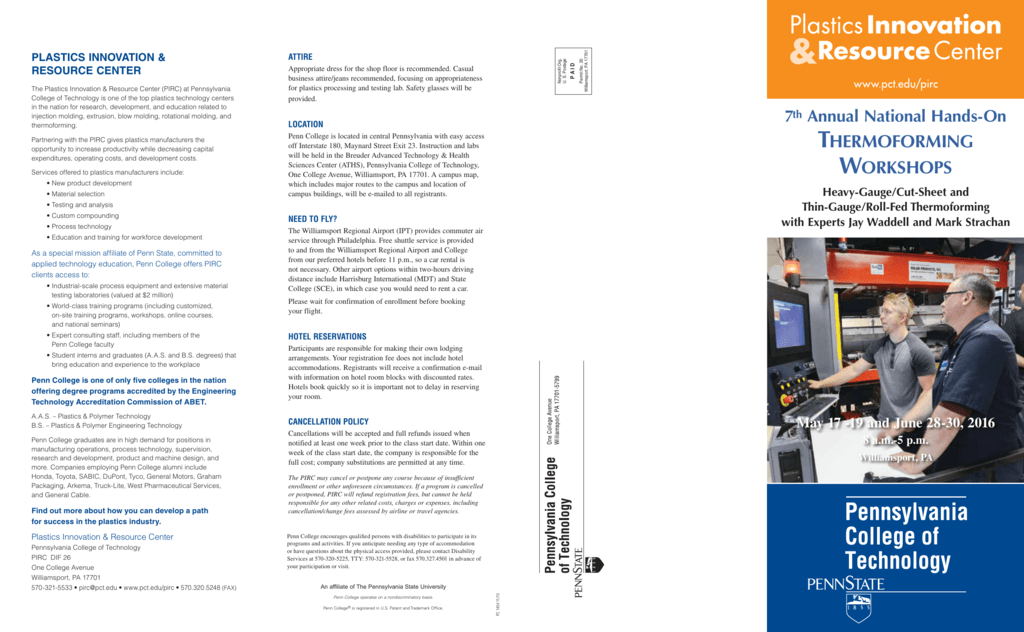

Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature formed to a specific shape in a mold and trimmed to create a usable product.

This causes the plastic that touches the mold to cool very abruptly and freeze onto the mold surface.

The molded plastic parts are then trimmed and inspected for.

Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature formed to a specific shape in a mold and tripped to create a usable product.

Thermoforming is a process that involves heating a flat sheet of plastic until it is soft enough to mold.

Overview of thermoforming thermoformable plastic sheets from professional plastics.

Next you actually drape the hot plastic sheet over the mold.

Thermoforming refers to the process of heating and shaping a plastic sheet on a mold.

1 sheet is heated to thermoforming temperature.

Amorphous plastics like abs and polycarbonate generally have wide processing windows and good melt strength making them easy to thermoform.

2 pressure forming equipment has features to lock together both sides of the pressure forming tool creating a seal on the plastic sheet.

Thermoformed pp with polyethylene pe sealing layer pp pe co extruded sheets that combine high quality polypropylene with an integral polyethylene sealing layer.

Once it reaches the right temperature the sheet advances to the form section.

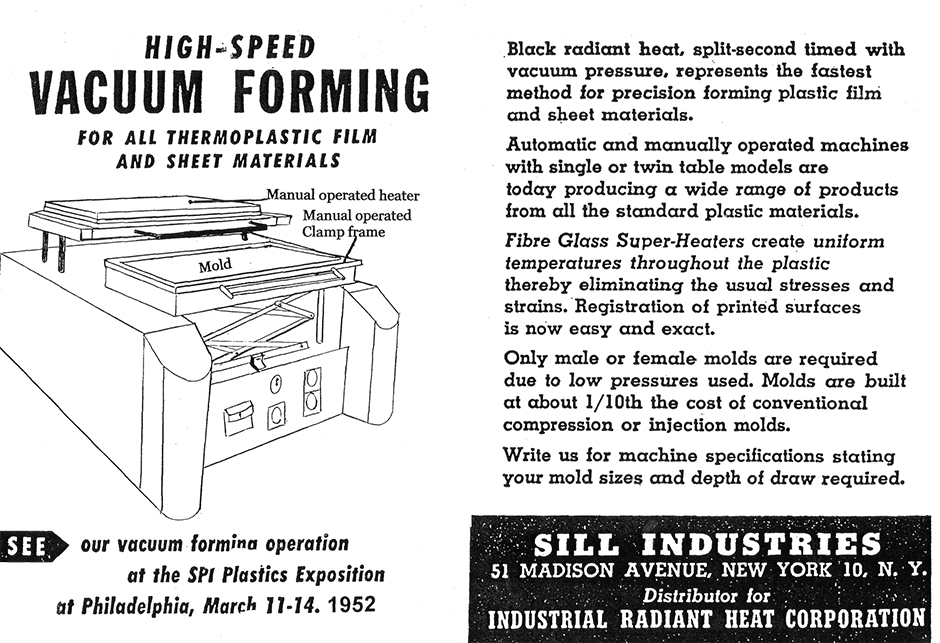

Thermoforming can range in complexity from manual operations to highly automated large scale ones.

Polypropylene pp sheets for thermoforming mono layer sheets supplied in thicknesses from 150 micron to 5mm suitable for simple food or non food packaging materials.

Thermoforming offers processing advantages over competitive processes such as blow molding and injection molding.

Some plastics like hdpe and pp have narrower processing windows and lower melt strength which make them more difficult but not impossible to thermoform.

Use these plastic sheets along with with our hobby vacuum formers and a kitchen oven to thermoform homemade plastic parts with results that rival expensive commercial machines.